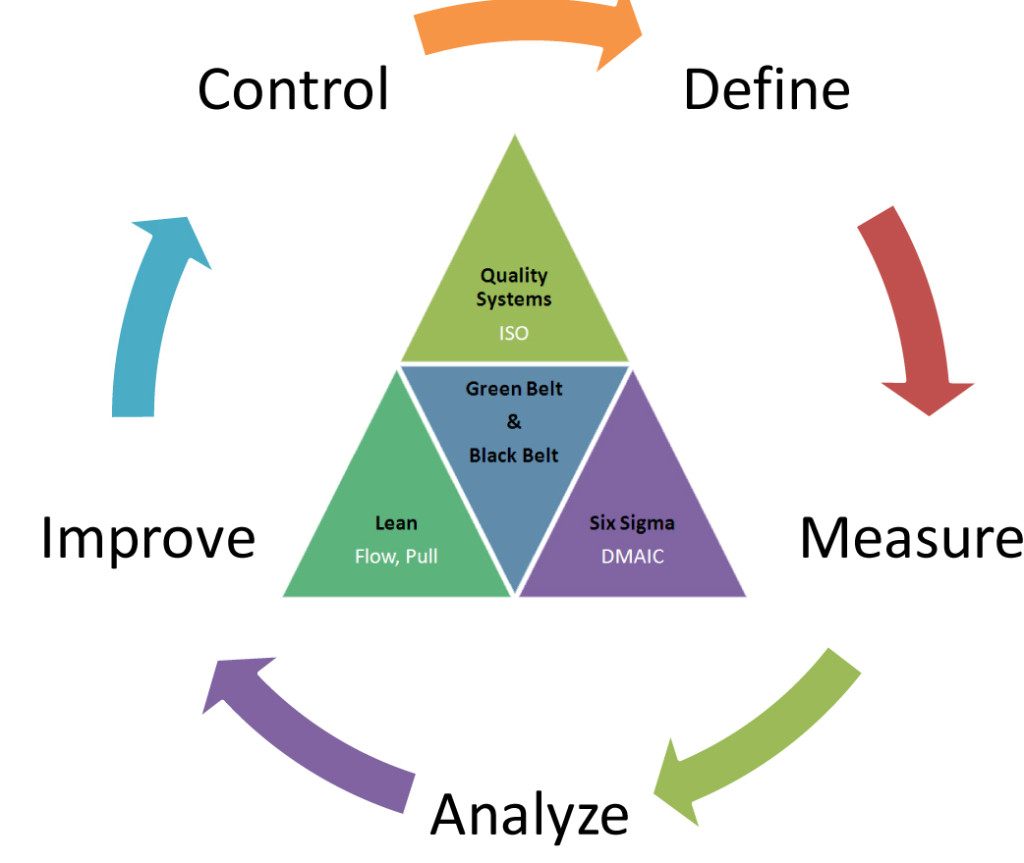

Six Sigma is a methodology that helps improve business processes by using statistical analysis. It is a data-driven and highly disciplined methodology and approach that ensures elimination of defects in any type of business or organizational process.

In order to achieve Six Sigma, organizational processes need to keep their defects to a maximum of 3.4 per million (99.99966%) opportunities. A Six Sigma defect can be defined as anything that is outside of client specifications. Its objective is to minimize the variability in business and manufacturing processes. One of the salient highlights is the ability to create focus on achieving quantifiable and measurable financial returns from any six sigma project.

Developed by Motorola in 1986, Six Sigma is basically a set of tools and techniques that enable process improvement.

Importance of Six Sigma

Six Sigma has come a long way since its implementation as a business strategy by Jack Welch at General Electric in 1995. Since then it has been widely implemented in several industrial sectors. Implementing Six Sigma is important as it will help organizations in several ways like:

Mapping or flowcharting of processes

Process mapping is utilized by Six Sigma, which can be defined as a process of flowcharting to enable documentation of a specific business process. Documentation includes various aspects of business processes like employee roles and decision points in overall work performance required for meeting specific client needs. These flowcharts are often used towards making improvement suggestion.

Elimination of variation and waste

After identification of improvement ideas, Six Sigma techniques can be used for elimination of waste and variation in business processes. Waste is defined as anything that doesn’t help in producing the service or product that is required to be delivered to a customer.

Reduced Defects

One of the reasons why implementation of Six Sigma is important is that it helps in reducing defects. Using Six Sigma techniques, employees are able to identify problem areas as well as recurring issues that affect the overall quality expectation of a service or product from a customer’s viewpoint.

Room for continuous improvement

Last but not the least, employees trained in Six Sigma processes have the necessary tools and skills to identify problem or bottleneck areas that camps down production or performance. This process helps employees to identify areas of improvement and work towards it continuously. At the end, it helps in improving existing services or products and assists with development of new high quality products.

Learn about other project management concepts in the Project Management Glossary.